Dye and Dyestuff Manufacturing Plants

Dye and Dyestuff Manufacturing Plants

Cost competitive plants with total pollution compliance for the dyes industry

Shachi Engineering has supplied some of the largest plants for Dyes and Dyestuff manufacturing in the world.

With a proven design, Shachi Engineering delivers highly cost-competitive drying and evaporation solutions for dyes and pigments manufacturing. We offer a complete range, from semi-automatic to fully automatic plants to meet every type of requirement and every budget.

Game-changing innovations in

Dye and Dystuff manufacturing.

- High-efficiency filters and a single scrubber capable that helps to reduce capital and operational costs while meeting all the pollution norms

- Self-Cleaning Evaporators when used in ZLDs have allowed plant operations for months together, without the need of any shutdown required for cleaning in case of conventional of evaporators

Get the best of both quality and cost economics

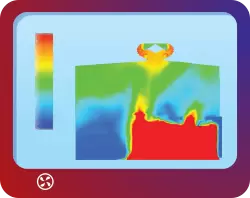

When it comes to dyes and pigments, Shachi Engineering’s expertise is wide and deep. Whether it’s perfecting the size and color of the particles for the dying effectiveness or technology that helps reduce the CAPEX and OPEX, Shachi’s designs, aided by CFD technology ensure precise output.

In the case of Dryers, Shachi Engineering has supplied plants with a production output of up to 10,000 Kg/hour which is one of the highest in the industry. Shachi Engineering has supplied Evaporators with a water evaporation capability of up to 3500 kg/hour. Both the plants are recognized to deliver a consistent performance in continuous operation, with significantly lower downtime and product losses as compared to the industry norms.

About 70% of Dyes and Dyestuff in India is manufactured using Plants supplied by Shachi Engineering

Why Shachi Engineering

Assuring total compliance

Compact and high-efficiency designs