ZLD Evaporation/Crystallization in Textile Industry

Textile Industry

Cost competitive plants with total pollution compliance for the textile industry

Challenges

Textile Wastewater Treatment

Processing, printing, and dyeing of 1 Ton Textiles typically consume up to 200 Tons of water. A large percentage (80% to 90%) of such water is discharged as wastewater. Additionally, the processing of textile chemicals, raw materials, reagents requires huge amounts of water.

- No uniform or standard method is available to treat textile effluents

- Large volumes of water to be treated at every stage

- Stringent environmental norms

- Increased costs from running and maintenance of ZLD plants

- Meeting the responsible business norms for global supply chain and exports

In order to stop pollution of stream water and groundwater, the Central Pollution electrical device (CPCB) of India has made the ZLD system necessary for all the extremely polluting industries including Textile colouring and Bleaching. ZLDs from Shachi Engineering, used by some of the largest Dyes manufacturers in the India, deliver total compliance without hassle for years together.

Revolutionizing economics of wastewater treatment in textiles

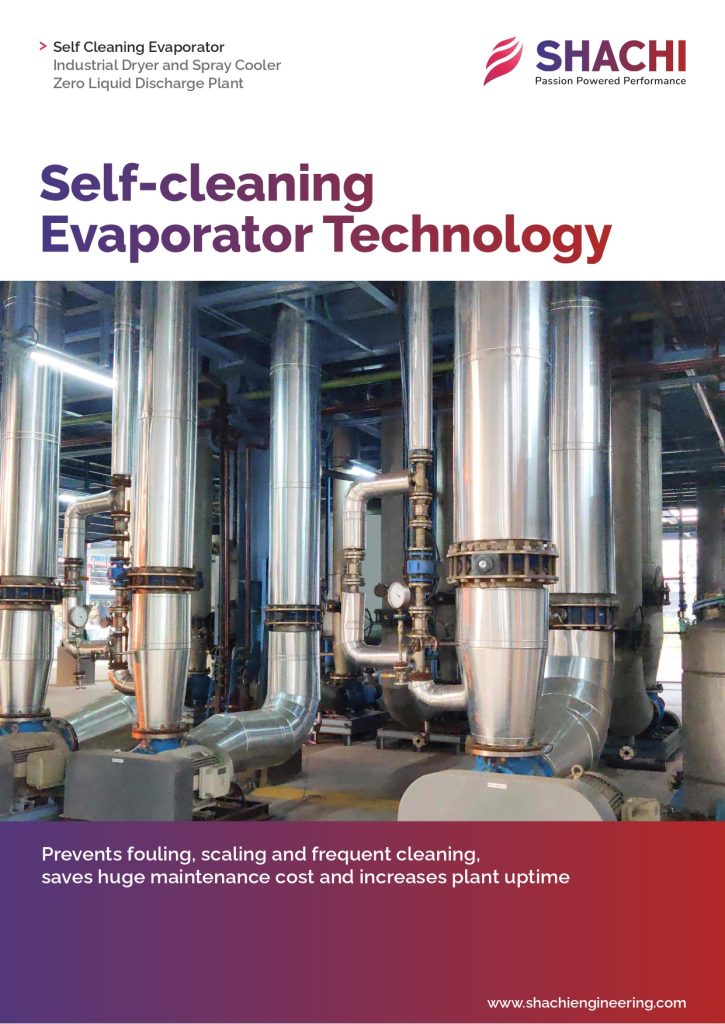

The innovative self-cleaning evaporator technology ensures ZLDs at minimum possible costs with continuous operations.

The innovative self-cleaning evaporator technology from Klaren International is revolutionizing the cost-economics of ZLDs in the textile industry. The technology is well proven for meeting stringent environmental norms for medium to large-scale textile plants in the processes of de-measuring, scouring, blanching, mercerization, coloring, printing, finishing up to the laundry.

Considering wide fluctuations in effluent parameters, it is challenging to prescribe one standard method to treat textile effluents. Shachi Engineering’s know-how ensures the right sequence for the treatment process with the best results. The innovative self-cleaning evaporator technology ensures ZLDs at minimum possible costs with continuous operations.