Multi Effect Evaporator

What is multi effect evaporator ?

Multi effect evaporator is a sophisticated and efficient industrial equipment used to concentrate solutions by evaporating the solvent. It consists of multiple evaporator vessels, known as effects, arranged in series. Each effect operates at a progressively lower pressure and temperature, utilizing the vapor generated by the previous effect to drive the evaporation process. This design maximizes energy efficiency and reduces operational costs.

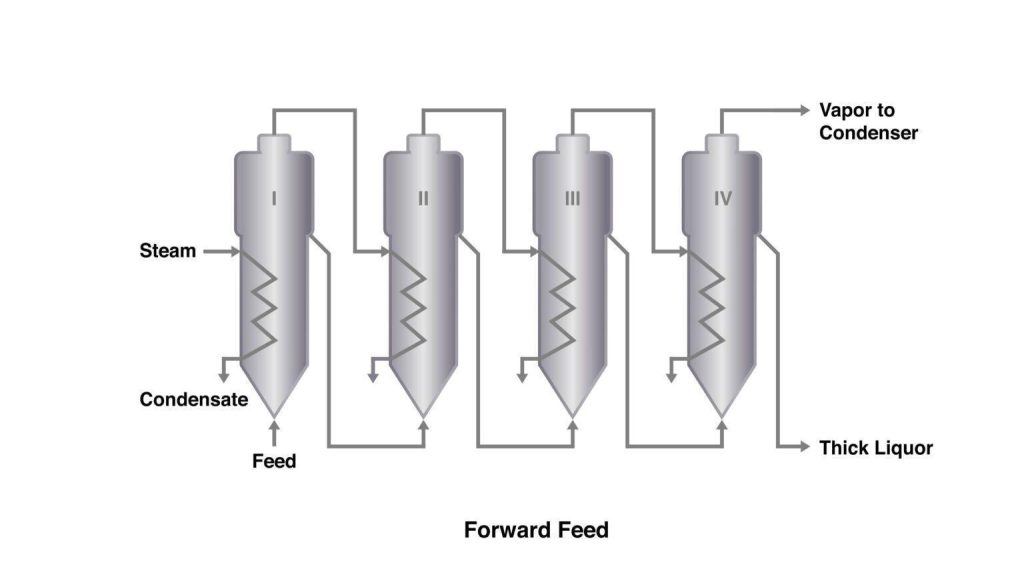

Forward feed multi effect evaporator:

The forward feed multi effect evaporator operates by introducing the feed solution into the first effect, where heat is supplied to cause evaporation. The generated vapor is then transferred to subsequent effects, heating the liquid in each stage and promoting concentration. With its efficient energy utilization and high concentration ratios, this compact evaporator design is suitable for various applications. It offers flexibility in handling different types of solutions and allows for precise process control. The forward feed multi-effect evaporator is widely used in industries such as food and beverage, chemical processing, desalination, and wastewater treatment, delivering efficient and sustainable solutions.

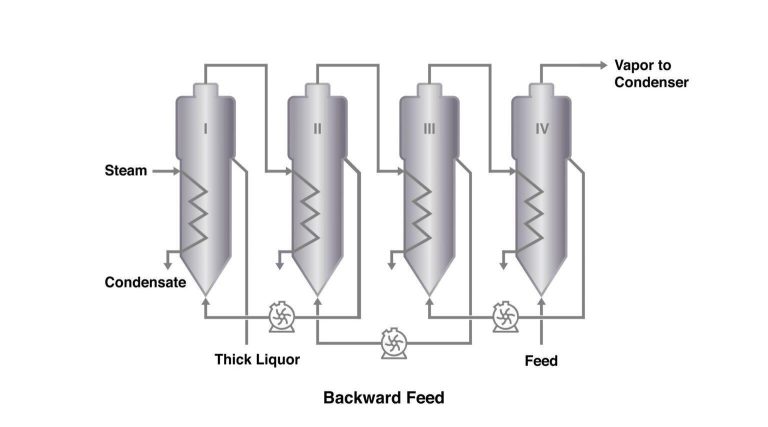

Backward feed multi effect evaporator:

The backward feed multi effect evaporator operates by introducing the feed solution into the last effect, where it is concentrated through evaporation. The vapor generated in the last effect is then transferred to the previous effect, heating the liquid in each stage and further concentrating the solution. This backward flow arrangement allows for optimal energy utilization and increased concentration ratios. With its efficient design, the backward feed multi-effect evaporator is suitable for various applications, offering flexibility in handling different types of solutions. It is commonly used in industries such as food and beverage, chemical processing, desalination, and wastewater treatment, providing efficient and sustainable solutions.

Benefits of multi effect evaporator:

- Energy efficiency: One of the main advantages of multi effect evaporator is their high energy efficiency. These evaporators utilize the heat generated from one effect to drive the evaporation in subsequent effects, resulting in reduced energy consumption compared to single effect evaporators. The heat is typically supplied in the form of steam, and the latent heat of vaporization from one effect is used to heat the liquid in the next effect, thus minimizing energy waste.

- Cost savings: Due to their energy efficiency, this evaporator can result in significant cost savings in terms of energy bills. By reusing the heat in subsequent effects, less external energy (in the form of steam or hot water) is needed, leading to lower operational costs over time.

- High concentration ratio: They are capable of achieving high concentration ratios, which is the ratio of the initial liquid volume to the final concentrated liquid volume. This is beneficial in processes where a high degree of concentration is required, such as in the production of concentrated fruit juices, dairy products, and chemicals. High concentration ratios result in reduced transportation and storage costs for concentrated products.

- Flexibility: It offer flexibility in operation and can be designed to handle a wide range of feed solutions with varying concentrations and viscosities. It can also be operated in a multi-stage mode, allowing for greater control over the evaporation process and the ability to achieve desired product specifications.

- Environmental sustainability: With the increasing focus on environmental sustainability, multi-effect evaporators are considered more environmentally friendly compared to other methods of concentration or dehydration. By utilizing waste heat or low-grade heat sources, multi-effect evaporators can help reduce greenhouse gas emissions and minimize the environmental impact of industrial processes.

- Product quality: They are known for producing high-quality concentrated products. The controlled evaporation process helps to preserve the sensory and nutritional properties of the original liquid, resulting in products with better taste, aroma, color, and nutritional value.

- Process integration: It can be easily integrated into existing process lines, allowing for seamless integration into existing production processes. They can be combined with other unit operations, such as crystallization, drying, and distillation, to create a more efficient and integrated production system.

Various types of multi effect evaporator:

- Self-cleaning evaporator

- Forced circulation evaporator

- Falling film evaporator

- Agitated thin film evaporator

- MVR evaporator

Applications of multi effect evaporator:

- Desalination: Multi effect evaporators are widely employed in desalination processes to convert seawater into freshwater. The energy efficiency of these evaporators makes desalination a more viable and sustainable solution for regions facing water scarcity.

- Food and Beverage Industry: In the food and beverage sector, they are used for concentrating fruit juices, dairy products, sauces, and various liquid food items. They help preserve flavors and reduce transportation costs by concentrating the product, thus minimizing volume.

- Chemical Processing: They also find extensive use in chemical industries for concentrating chemical solutions, separating solvents, and recovering valuable products. Their versatility and energy-saving nature make them valuable assets in chemical processing plants.

- Wastewater Treatment: They play a crucial role in wastewater treatment processes. They concentrate the waste stream, allowing for easier disposal or further treatment. The recovered water can be recycled, minimizing water consumption and reducing environmental impact.

At Shachi Engineering, we are committed to providing high-quality multi effect evaporators tailored to meet your specific requirements. Our cutting-edge solutions are designed to optimize energy usage, enhance productivity, and minimize environmental impact. With our expertise and dedication to customer satisfaction, we guarantee reliable and efficient equipment for your challenging needs.