An award winning company

Zest Aroma is an award winning company that offers aesthetically superior and most competitive flavours and fragrances and flavours that match stringent global quality standards. The flavours and fragrances are used and blended with products of leading Indian and international brands. The company is also recognised for its high sensitivity to environmental issues and has one of the most advanced systems for processing of harmful waste from its plants.

Challenge

Safety and Quality

Flavours and Fragrances are highly volatile products. It becomes a critical challenge in the drying process. Additionally, the manufacturing process has to comply to one of the most stringent safety and quality norms for any products.

Risk of Explosion

The volatile nature of the product means the plant is prone to risk of explosion and has to have all the checks to arrest fire, if it occurs, at its root. The plant had to have the right balance in ensuring safety, quality and performance for Zest to have a profitable product line in years to come.

Shachi Engineering was entrusted with the critical task, owing to its long standing expertise and a strong reference list for plants that manufactured ‘quality’ products.

Solutions

Ensuring quality

Safety and quality were critical to the very functioning of the plant at Zest Aroma. Shachi’s team invested time to understand the specific requirements, its linkages within the process stages before designing the solution. With a comprehensive understanding of the process, Shachi Engineering was able to propose a solution that not just met the Client’s manufacturing need but would also allow the staff to drive production confidently.

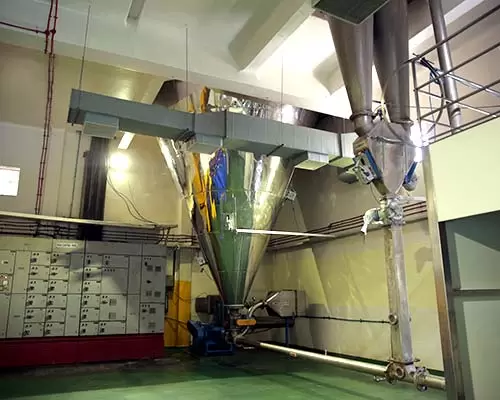

Arresting Safety Challenges

To ensure safety the Spray Dryer plant was integrated with several fire arrestors, at critical points. The accessories and automation in the plant had to be all certified for fire resistance. Even the doors used to access the plant were with an explosion proof design. Safety was critical can be gauged from the fact that the investment in Spray Dryer plant and that on measures to improve the safety were almost equivalent. Shachi’s Spray Dyer was embedded with logic for enhanced safety. The robust construction, quality workmanship and engineering further ensured highest order of safety and quality for Zest’s products.