Revolutionary

Self-cleaning Evaporator

Dryer

We have 20 years of experience and have supplied more than 250+ industrial dryers for 100+ applications.

Evaporator

Prevents fouling and frequent cleaning, saves huge maintenance cost and increases plant uptime.

Spray Cooler

Successfully manufactured & delivered several open and closed loop spray coolers for critical industry applications.

ZLD Plant

Shachi's Zero Liquid Discharge Plant is economical in operation and meets the stringent pollution control norms.

Served 100+ Applications

◎ Dyes

◎ Acid dyes

◎ Reactive Dyes

◎ Disperse Dyes

◎ Dye Intermediates

◎ Metal Complex Dyes

◎ Dispersing Agent

◎ Tanning agent

◎ Pigments

◎ Agro Chemical

◎ Phosphates

◎ Urea Formaldehyde

◎ Resin & Phenol Resin

◎ Calcium Chloride

◎ Ceramic for tiles

◎ Technical Ceramics

◎ Composite Minerals

◎ Effluents

◎ Hydrogenated Castor Oil

◎ Stearic, Fatty Acid

◎ Palm Stearin

◎ Pharmaceuticals

◎ Sodium Propionate

◎ Spirulina

◎ Herbal/Medicinal Plant Extracts

◎ Vitamin B-12

◎ Enzymes

◎ MCCP

◎ Flavors, Fragrances

◎ Instant Tea and Coffee

◎ Fruit Juices

◎ Milk Powder

◎ Banana Puree

What sets us apart?

Proven Performance

With Shachi’s innovative design and quality engineering, you are assured of high-performance equipment and plants that perform as promised on every parameter.

Proactive Approach

Shachi has always led from the front. From identifying challenges before you face them to building and delivering solutions that are geared to meet your future needs, Shachi’s proactive approach is evident in every task.

End-to-end Capabilities

From concept to final commissioning and beyond, you can rely on Shachi's expert team to gauge and successfully solve the foreseen and unforeseen challenges at every step in your processes.

Clients Speak

Prashant Shah, DGM – Accent Microcell Pvt. Ltd.

Shachi supported us from the inception & offered us the best spray dryer & we are happy with the performance.

Prashant Shah- DGM – Operation-Ascent Microcell Pvt. Ltd.

We express sincere thanks to you for supplying Spray Dryer technology which has resulted into seamless operation. The plant provided great hygiene standards, critical for MCCP. we are extremely delighted with performance of Spray Dryer from Shachi Engineering.

Harsh Patel, Director – Yashasvi Rasayan Pvt. Ltd.

Shachi’s team provided valuable insights from the design to final commissioning stage. The team of Engineers was knowledgeable and well versed with technology and functional expertise in multi-effect evaporators. I am thankful to Mr. Shanbhag and the team for all the support.

Mukesh K. Agarawal – Zest Aromas Pvt. Ltd.

Shachi Engineering has supplied and installed spray dryer plant to our company for flavours and fragrance application and the plant is operating satisfactory and efficiently.

Amar Pahuja-Project Manager-Gujarat Fluorochemicals Limited

Shachi Engineering successfully supplied triple effect evaporator and spray dryer plant for our calcium chloride project. The installation was completed well within timelines. We recognize Shachi’s plant as very good based on parameters like quality of workmanship, technical proficiency, financial soundness and resourcefulness.

O P Gupta-Project Manager-Department of Atomic Energy-Heavy Water Board

Shachi Engineering successfully provided complete assistance from design to installation for Elemental Boron Plant. We found their Multiple Effect Evaporator plant very good based on parameters like quality of workmanship, technical proficiency, financial soundness and resourcefulness.

Key Clients

Blogs

Zero Liquid Discharge (ZLD) systems are designed to help industries

Spray Dryer Design: Simple in Appearance, Complex in Reality

At first glance, a spray dryer machine seems straightforward liquid

How CFD Improves Spray Dryer Design for Accuracy and Predictability

Spray drying works best when airflow, droplet formation, residence time,

ZLD for APIs: Evaporate, Separate, Dry and Reuse

APIs are the molecules that make medicines work, and their

Shachi Beading Plant: Built for Global Performance

With installations across India, South East Asia, the Middle East,

Why Particle Size Matters! How Shachi delivers exact particle sizes

Open any bag of powder, may it be nutraceutical premix,

Spray Cooler vs Beading Plant: 5 Key Differences Every Oleochemical Producer Should Know

When it comes to solidifying molten fatty acids, glycerides, or

Celebrating 27 years of Shachi Engineering

A Journey That Started with Clarity and Commitment In 1998,

World Environment Day – 2025

Stand behind almost any factory and you’ll find it.A quiet

Understanding Spray Cooler | Beading Plant | Spray Congealing for Fatty Acid Processing

Spray congealing is a continuous process that converts molten materials

When a large stainless steel manufacturer in India planned a

When an existing client returns for a second plant, it

Ana Plant Commissioned

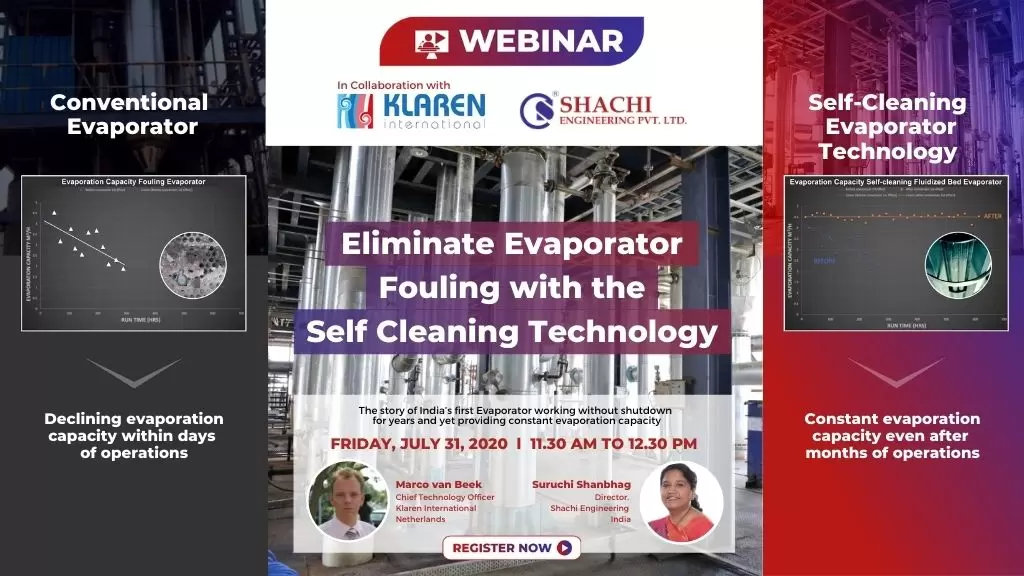

Shachi Engineering, in collaboration with Taprogge-Klaren, is proud to announce

Shachi Engineering’s Green Commitment

At Shachi Engineering, we’re dedicated to protecting our planet. This

From Strangers to a Family – Shachi’s Induction Program

Joining a new company can be a nerve-wracking experience, but

5 Things to do at Dahej Industrial Expo 2023

Dahej, with its industrial significance and coastal location, plays a

Devendra’s journey began while pursuing his Bachelor’s in Engineering. Fueled

Two Sides of Sustainability

Sustainability is a term that resonates with us all, emphasizing

Gaurav’s Growth Story – Remarkable Journey from Engineer to Leading a Prestigious Project in Under 8 Months

The urge to change… When there is a genuine urge

Factors to be considered in spray drying process

Spray drying process removes the moisture from liquids to turn

Eliminate Evaporator Fouling with the Self Cleaning Technology

Webinar | Eliminate Evaporator fouling with the innovative self-cleaning technology

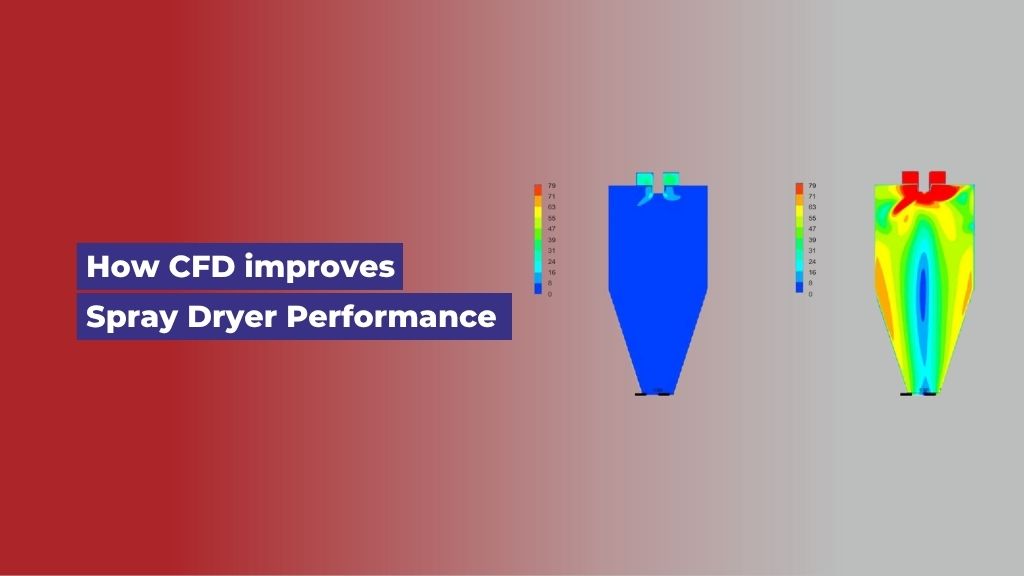

How CFD improves Spray Dryer Performance

When the stakes are high, knowing what is going to

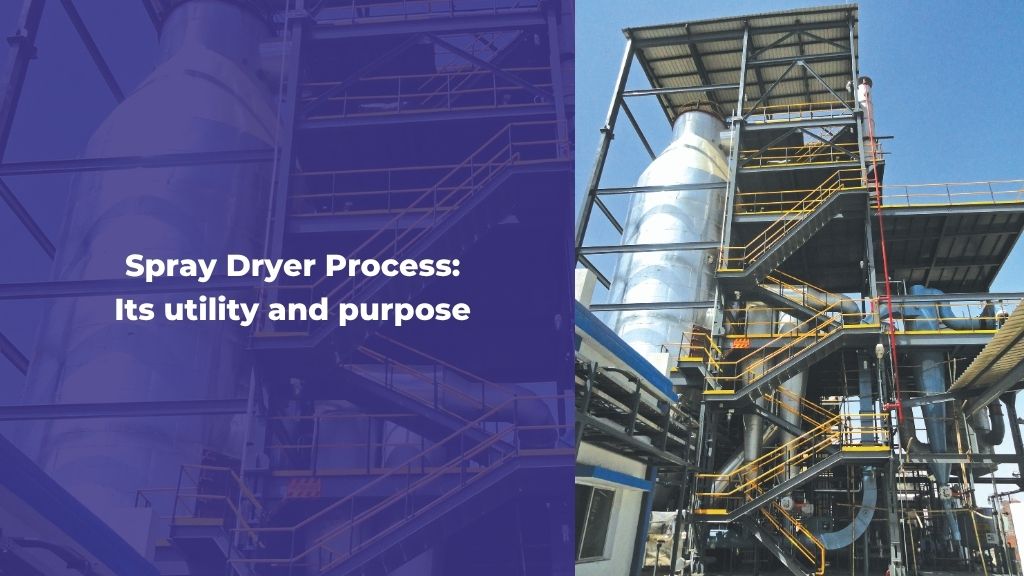

Spray Dryer Process: Its utility and purpose

How do you produce 28 tonnes of milk powder in

Advantages of Computational Fluid Dynamics

When life is surrounded by uncertainty and the stakes are

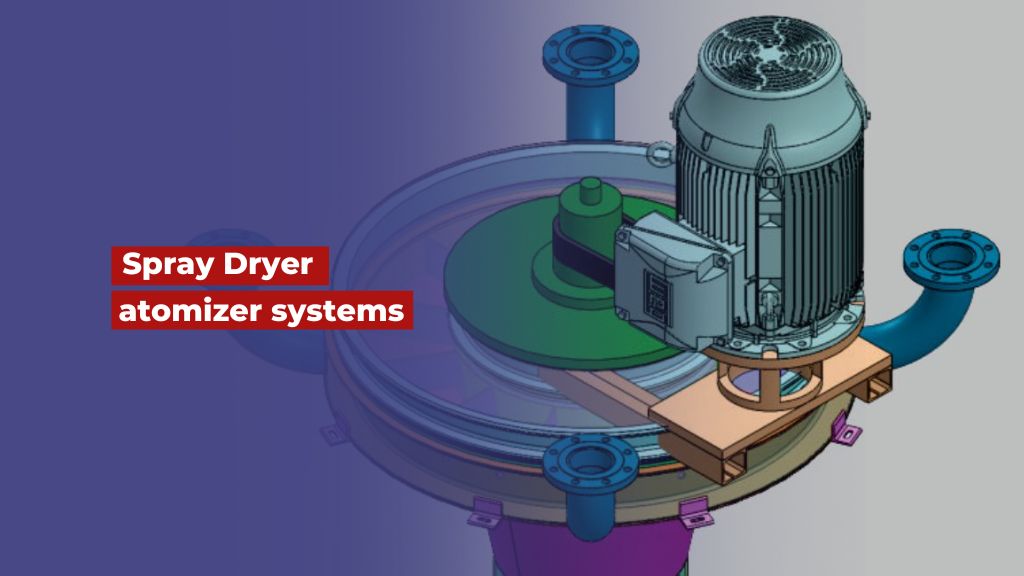

Spray Dryer atomizer systems

How would chopping vegetables with a knife that has lost

Spray Dryer Maintenance

Spray Dryer Maintenance – Deposition problem in the dryer chamber

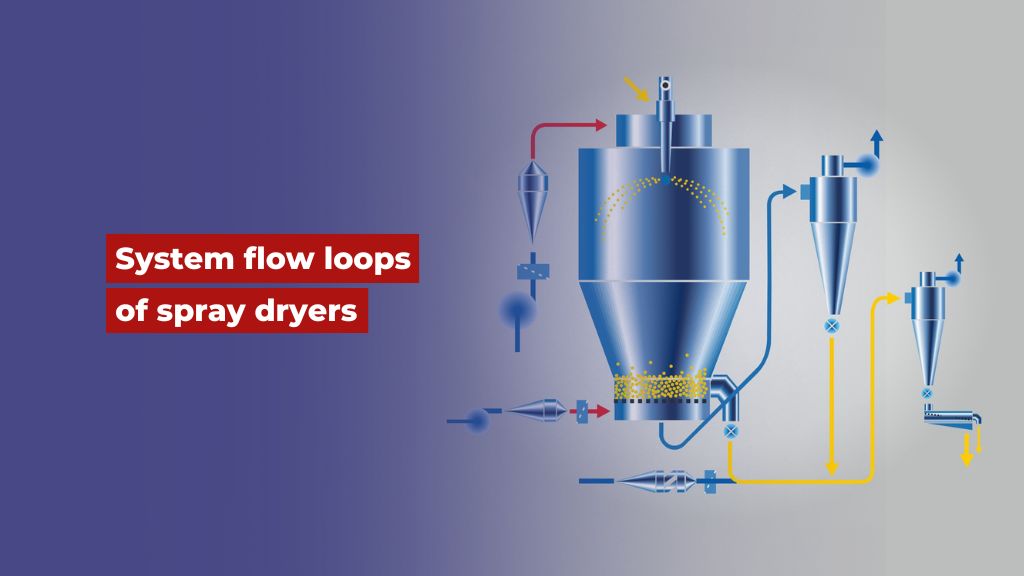

System flow loops of spray dryers

Explosives and pharmaceutical products are some of the sensitive materials

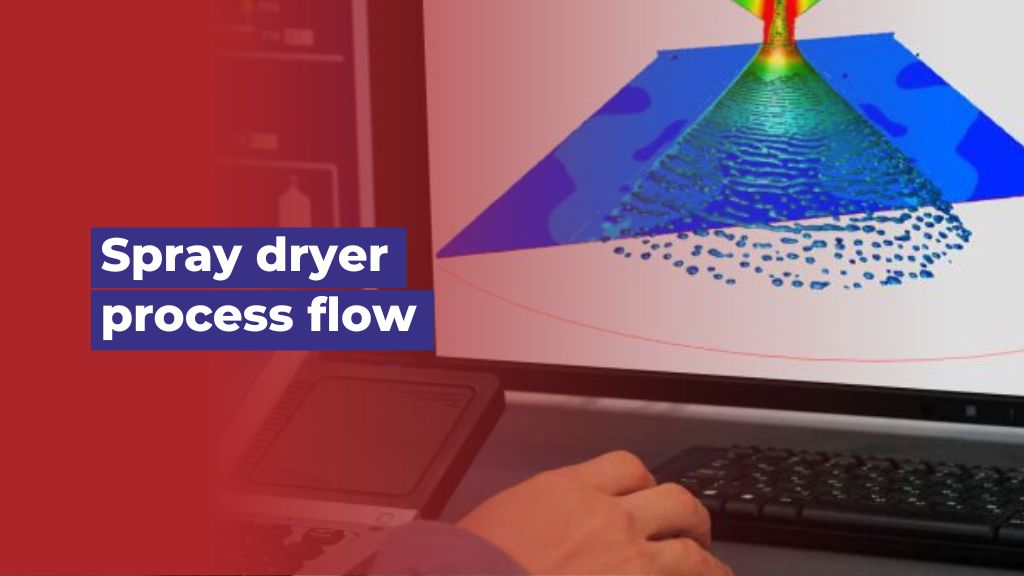

Spray dryer process flow

Quantity and quality are generally perceived to be on the

Spray Dryer History

We generally like to forget moments when we end up

Shachi’s strategic technology collaboration with a niche European Company helps

Spray Dryer Process for Flavours in Food and Cosmetics

Production of dry flavorings is achieved easily with spray drying.

Spray Dryer technology to improve your product quality

Spray Dryer – Technology and Art! Spray Dryer is both

News

Solving Today’s Water Challenges: Shachi Engineering at IFAT 2024

This October, Shachi Engineering will showcase its expertise at IFAT India 2024, which

Shachi Celebrating Engineer’s Day

Engineer’s Day is a celebration of those who dream in

Shachi Foundation Day 2024

Shachi Foundation Day 2024 Shachi Engineering’s 26th Foundation Day was

Celebrating Phenomenal Growth and Success!

Over the past half-year, Shachi Engineering has achieved remarkable success

Sharing Insights gained from 100+ Industry Leaders at IFAT INDIA 2023

In case you missed visiting Shachi Engineering’s Booth at IFAT

Exploring Sustainable Solutions with Shachi Engineering at IFAT India 2023

In the heart of Mumbai, a momentous event is on

Engineers Day – Then and Now Honouring Sir Mokshagundam Visvesvaraya’s Legacy

Every year, on September 15th, India celebrates Engineers’ Day in

Shachi Engineering, a leading industrial drying and evaporation solutions provider,

Shachi Engineering gets recognized as “Emerging ESG Partner”

Shachi Engineering, the leading industrial drying & evaporation solutions company

Shachi Launched New Brand Identity, Brand Promise and Core Company Values

Shachi has launched a new brand identity, brand promise and

Celebrated our 23rd Foundation Day Anniversary

On 14th July 2021, Shachi Engineering celebrated its 23rd Foundation

Shachi won the Rotary Environment Excellence Award

At Shachi, we are committed to provide sustainable technology solutions

Spray drying plant with advanced PLC control systems

For one of the maharatna company in India, Shachi Engineering has

Invitation for Industrial Expo 2021

Meet Shachi Engineering’s Team at “Industrial Expo” Dahej – from April

Sales Training Program – Shachi Engineering

At Shachi Engineering, we believe in improving customer experience by

Invitation for Industrial Expo 2021

Visit us at Industrial Expo, Ankaleshwar 2021, at Hall No:

Happy New Year 2021

Happy New Year 2021 During covid-19 pandemic, opportunities were disappearing…

Inauguration of New facility – at GIDC-Saykha, Bharuch, Gujarat

Towards a bigger and brighter future! Shachi Engineering now stands

New Age IIoT Enabled Evaporators

Evaporation is a highly energy-intensive process. Typically, it consumes 15%

There are two types of office goers. The passionate and

Meet Game-changing Innovations at Chemtech 2019

Enhancing productivity is a perpetual mission. In the quest to

We are soon going to be in Dahej!

Shachi Engineering recently acquired land in Dahej to expand its

Shachi Engineering marks presence at Achema 2018

Shachi Engineering participated in the recently held Achema 2018 Expo