Self Cleaning Evaporator

Set new benchmark with revolutionary, Self Cleaning Evaporator

Prevents fouling and frequent cleaning, saves huge maintenance cost and increases plant uptime

Benefits

Better energy performance

Because tubes remain clean and the heat transfer is constant

Sustainable

Because chemicals are not required as online additives or needed for cleaning purposes and there are no hazardous waste streams from cleaning

Enhanced productivity

Because equipment does not have to be taken out of production for cleaning, capacity remains constant, and in some cases the production yield can be increased

Compact design

Because of constant heat transfer no over dimensioning is required

Webinar (Recording) Self-cleaning Heat Exchanger Technology

In this webinar the Self-cleaning Heat Exchanger Technology is explained.

The following topics are addressed:

- Fouling

- Operating principles

- New versus Revamp

- Applications

- References

Applications

- Effluent Treatment

- Chemicals

- Oil & Gas

- Food

- Mining

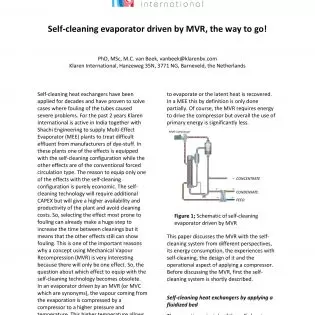

Significant Energy Savings with Mechanical Vapor Recompression

With the additional use of mechanical vapor recompression, 41% of the primary energy used in self-cleaning process can be saved. In this process, the vapor coming from the evaporator is compressed to increase its pressure and temperature, and can be used in the shell side of the heat exchanger where it condenses. Thus, the energy used in evaporating the latent heat is recovered and the dependence on primary energy is significantly reduced.