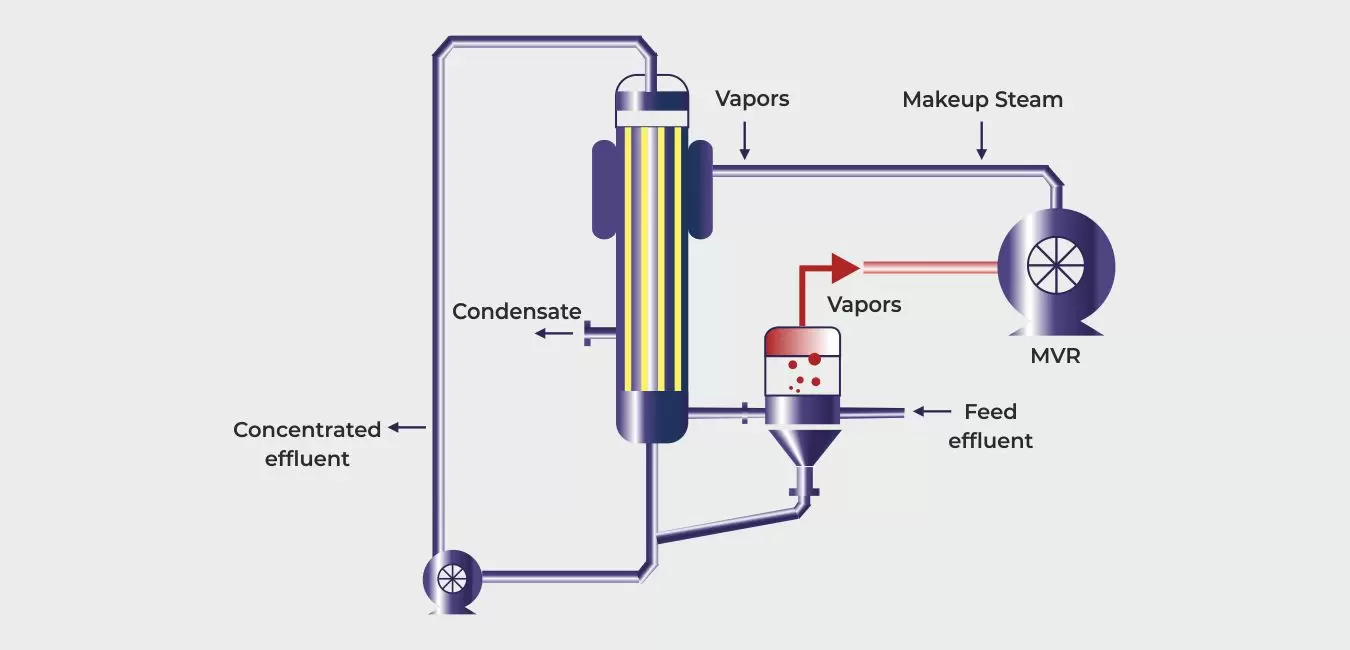

ZLD for APIs: Evaporate, Separate, Dry and Reuse

APIs are the molecules that make medicines work, and their effluents are some of the hardest to treat. Beyond GMP requirements, plants face strict environment norms on TDS/COD/BOD, solvent handling, and safety. Many facilities are expected to run Zero Liquid Discharge (ZLD) or close to it. The goal is simple: prove compliance, keep production moving, … Read more